A Beginner’s Guide to Performing Flame Scans

A Beginner's Guide to Performing Flame Scans

Flame scans are a vital yet often overlooked aspect of safety and maintenance in various industries. Picture this: a tool that can detect potential hazards before they escalate into serious problems. Whether you’re managing an industrial site, working with HVAC systems, or overseeing any operation involving combustion equipment, flame scans can be your best ally.

But what exactly is a flame scan? How do you perform one effectively? And why should you prioritize it in your routine checks? This beginner’s guide will walk you through everything you need to know about flame scans—from their purpose and benefits to the essential steps for executing them safely. Get ready to enhance your understanding and elevate your safety protocols!

Understanding the Purpose and Benefits of Flame Scans

Flame scans play a crucial role in ensuring safety across various industries. They help detect and prevent potential hazards related to flame emissions. By identifying leaks or improper combustion, these scans can significantly reduce risks.

The benefits extend beyond safety. Regular flame scanning can enhance operational efficiency. When equipment operates optimally, it saves energy and cuts costs.

Moreover, compliance with regulatory standards becomes easier with consistent monitoring. Flame scans demonstrate a commitment to maintaining workplace safety.

Industries such as oil and gas, manufacturing, and power generation all rely on flame detection systems for smooth operations. These scans not only protect personnel but also safeguard equipment from damage caused by uncontrolled flames.

By investing in regular flame scanning practices, businesses ensure both the well-being of their workforce and the longevity of their assets.

Preparing for a Flame Scan: Equipment and Safety Measures

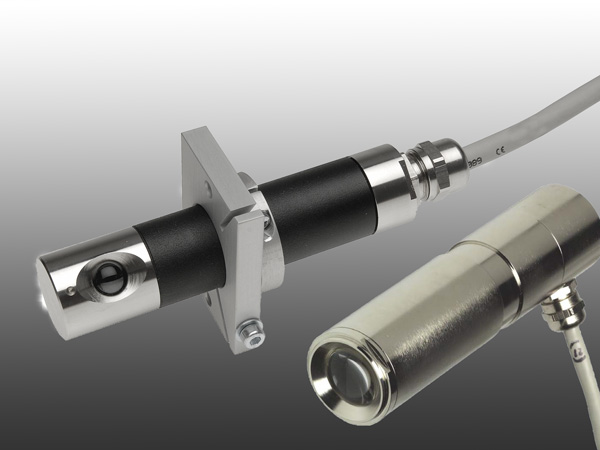

Before embarking on a flame scan, it’s crucial to gather the right equipment. You’ll need a reliable thermal imaging camera or an infrared thermometer. These tools help detect temperature variations indicative of heat leaks or issues.

Don’t forget personal protective gear. Safety goggles and gloves are essential for protecting yourself from potential hazards during the scanning process.

It’s also wise to prepare your workspace. Ensure that the area is well-ventilated and clear of obstructions. This not only facilitates easier movement but also enhances safety while performing scans.

Familiarize yourself with emergency protocols relevant to your location. Knowing how to respond quickly can make all the difference in critical situations encountered during flame scans. Taking these steps ensures you’re set up for success before diving into this essential procedure.

Step-by-Step Guide on How to Perform a Flame Scan

Start by gathering all necessary equipment. You’ll need a reliable flame scanner, suitable sensors, and calibration tools. Ensure you have personal protective gear like gloves and goggles.

Next, choose the right location for your scan. It should be near potential ignition sources or areas with high flammable material presence.

Once you’re set up, calibrate your equipment according to the manufacturer’s instructions. This step is crucial for accurate readings.

Now it’s time to initiate the scan. Activate your flame scanner while monitoring environmental conditions such as wind direction and humidity levels that can affect results.

As the scan progresses, pay close attention to any irregularities in data collected by the sensor system. Document everything for future reference; this will help you analyze trends over time.

After completing the scan, safely shut down all equipment following proper protocols to maintain safety standards at your facility.

Interpreting and Analyzing the Results of a Flame Scan

Interpreting the results of a flame scan requires careful attention to detail. Start by examining the intensity of the flame signatures captured during your scan. Bright, consistent flames often indicate optimal combustion conditions.

Look for any irregular patterns or flickers in the data. These may signal inefficiencies or potential hazards that need addressing. Pay special attention to variations across different zones within your equipment; this could help pinpoint specific issues.

Analyzing the temperature readings is equally crucial. Higher-than-normal temperatures can suggest trouble areas requiring immediate action. It’s essential to compare these results with historical data for better context.

Do not overlook environmental factors that might influence your findings, such as air flow and fuel quality. Understanding how these elements interact with your system will provide deeper insights into overall performance and safety levels.

Common Mistakes to Avoid During a Flame Scan

When performing flame scans, several common mistakes can compromise safety and accuracy. One frequent error is neglecting to conduct a thorough equipment check beforehand. A malfunctioning device can yield incorrect readings.

Another pitfall is rushing through the scanning process. Taking your time ensures that you capture all relevant data and reduces the likelihood of missing critical areas.

Not adhering to proper safety protocols is also risky. Always wear appropriate personal protective equipment (PPE) and ensure that your surroundings are safe before beginning the scan.

Additionally, failing to document results carefully leads to confusion later on. Clear records help track changes over time and inform maintenance decisions.

Ignoring environmental factors like wind or temperature may skew your results. Being aware of these elements enhances the reliability of your findings during a flame scan.

Applications of Flame Scans in Different Industries

Flame scans play a crucial role across various industries, enhancing safety and operational efficiency. In the oil and gas sector, they are vital for detecting hydrocarbon leaks, helping to prevent catastrophic failures.

Manufacturing facilities utilize flame scans to monitor combustion processes. This ensures optimal fuel usage while minimizing emissions. Regular checks can lead to cost savings and improved environmental compliance.

In the food processing industry, flame scans assist in maintaining safe cooking temperatures. They verify that equipment operates correctly, preventing potential hazards or product spoilage.

Even in waste management, flame scans help identify volatile organic compounds during incineration processes. This ensures a cleaner process and adherence to regulations.

Healthcare facilities also benefit from these scans by ensuring that sterilization equipment functions properly. Flame detection contributes significantly to patient safety by maintaining sterile environments.

Conclusion: Importance of Regular Flame Scans for Safety and Maintenance

Regular flame scans play a crucial role in ensuring safety and maintenance across various industries. By identifying potential issues before they escalate, these scans help prevent accidents and costly repairs. Consistent monitoring keeps equipment functioning optimally while enhancing overall efficiency.

Incorporating regular flame scans into your maintenance routine is not just a best practice; it’s essential for safeguarding personnel and assets. Staying proactive can significantly reduce risks associated with fire hazards, making it an indispensable part of operational strategies.

By prioritizing this vital procedure, organizations can foster a safer work environment while extending the lifespan of their equipment. Embracing the importance of flame scans ultimately translates to better performance and peace of mind in any setting where combustion processes are present.